Inspection of a non-working 500 watt 10 bar stack made by HPL. What a burnt bar looks like under a microscope. Article prepared by expert Romshi.

Laser expert Romshi cited the example of a 500-watt diode stack with one bar burned out. This article will help you learn in advance what problems with a malfunctioning ‘heart of a diode laser handpiece’ look like. Photos taken with a microscope will be an interesting addition to the article.

MOST IMPORTANT:

If you are having problems with the operation of the diode laser handpiece, the laser module has burned out, or you simply do not understand the problem, I STRONGLY RECOMMEND THAT YOU CONSULT WITH ME TO SAVE TIME.

If you are a beginner in repairing cosmetology equipment, then I hope you will be interested in reading the information. I represent a manufacturer of diode stacks, which will allow you to purchase a spare diode stack without intermediaries.

Also, these articles will be useful if you want to solve possible problems with your cosmetology equipment yourself. But it is better to consult and thank you for visiting the site.

This article by Romshi on diode stacks is for informational purposes only, and I do not recommend disassembling your laser handpiece and diode stack if your diode laser is working properly. However, the purpose of this section is to show beginners how hair removal lasers work and to help them with DIY repairs. Free consultation by phone +79180110234 in messengers WhatsApp, Telegram.

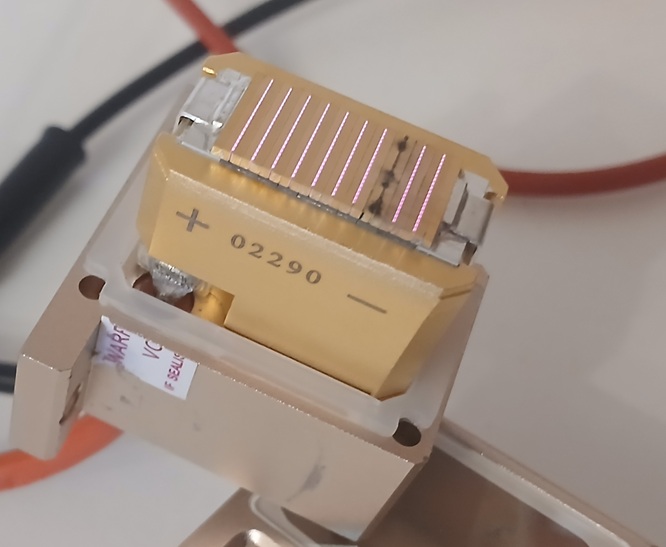

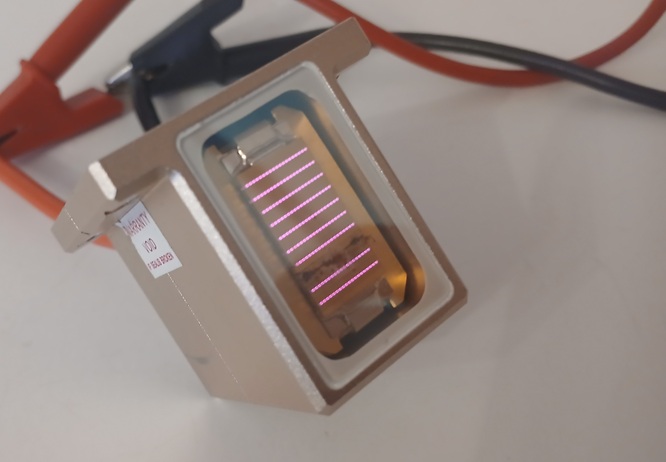

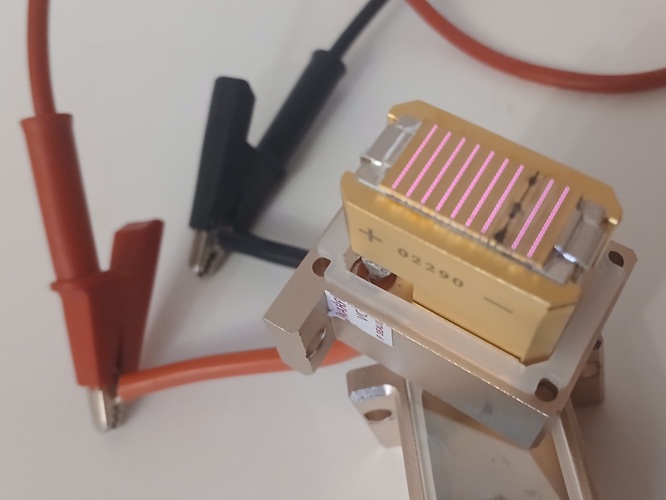

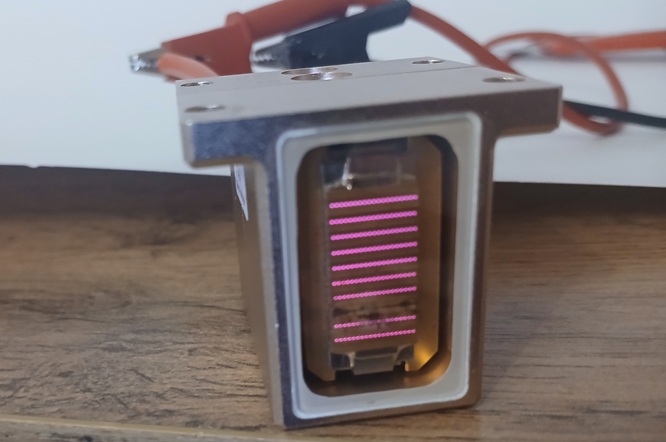

The photos below show a 500-watt 10-bar diode stack with a wavelength of 808 nm. This laser module power is quite common and is one of the options found in diode laser handpieces. In this case, 1 bar out of 10 burned out. Each bar can emit up to watts per ampere if a current of 50 amperes passes through it.

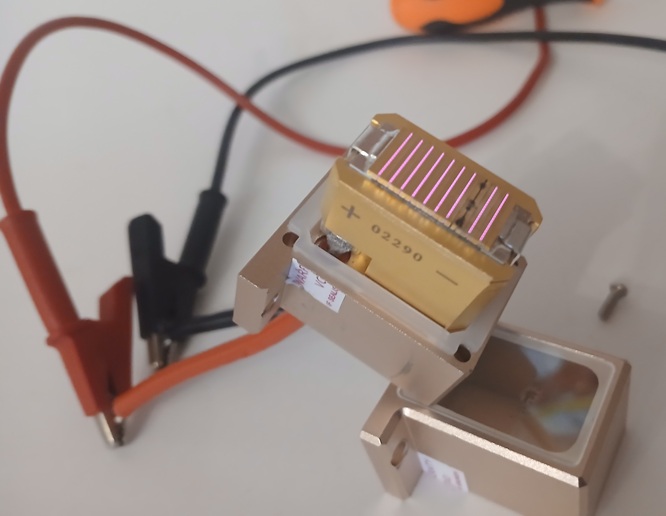

A customer reported that their cosmetic laser had stopped emitting flashes. The model of the cosmetic laser was ALD-1. The customer was asked to send a photo of the diode stack through the window in the handpiece. It was visually clear that the laser module was overheating. There were no flashes at all in the device because the power supply's current protection had been triggered. Only with the help of a separate laboratory power supply unit in the service centre can it be seen that 9 out of 10 plates are lit.

What are the main reasons for the failure of this diode stack? The main reason is overheating of the water and, accordingly, the diode matrix itself. The ideal water temperature is 23 degrees Celsius in the water system of a cosmetic laser. However, I would like to note in this article that the speed of water circulation in the diode laser system is also important. Therefore, it is important to change the filters for cleaning the water system in accordance with the instructions of the laser manufacturers. For Chinese diode lasers, the period is from 3 to months. I would like to note that water filters are usually installed in cosmetic lasers with polypropylene or ion resin. Sometimes both filters or double filters are used. These issues will be discussed in other articles on the website. Another important factor is the frequency at which the flashes are emitted. Ideally, it should be no more than 5 Hz. Also, the lower the power in the settings, the longer the diode stack will last.

In this case, 17 volts and 1.3 amps are supplied to the diode stack for 1 second using a laboratory power supply unit.

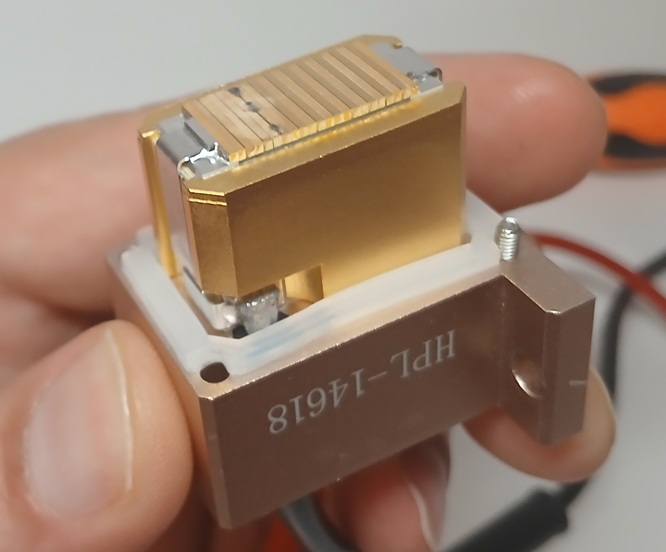

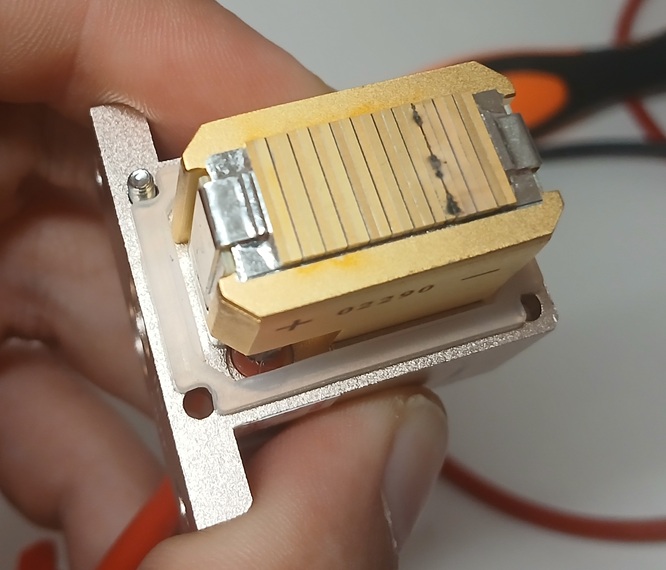

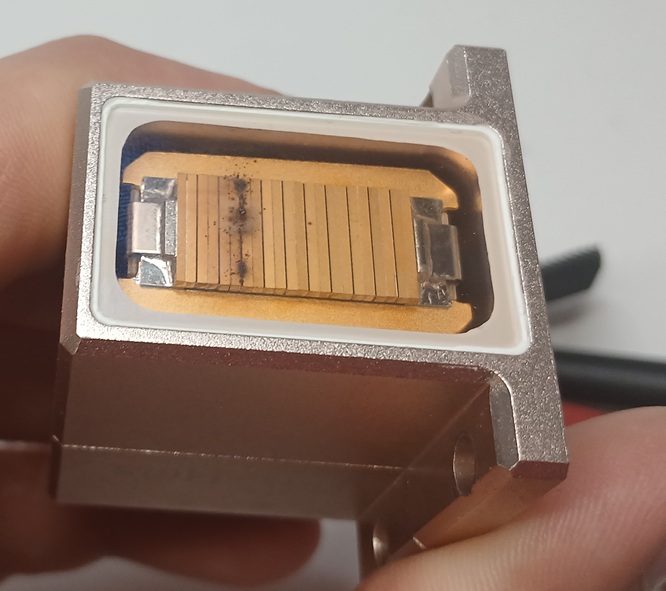

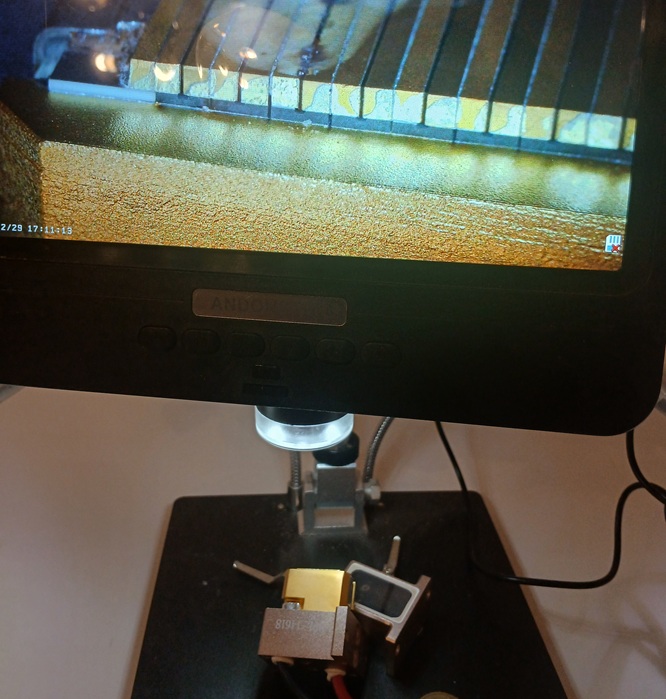

The photo below shows an open diode stack casing for demonstration purposes to readers of my website. However, I do not recommend that you disassemble new working parts, as this may lead to malfunctions. The stack is marked HPL, but in your case, the old diode stack may be marked lst, dvs, ht, hr, hd, or various other markings. Stacks differ in the quality of their bars. We offer DVS and LST diode stacks and are confident in their quality.

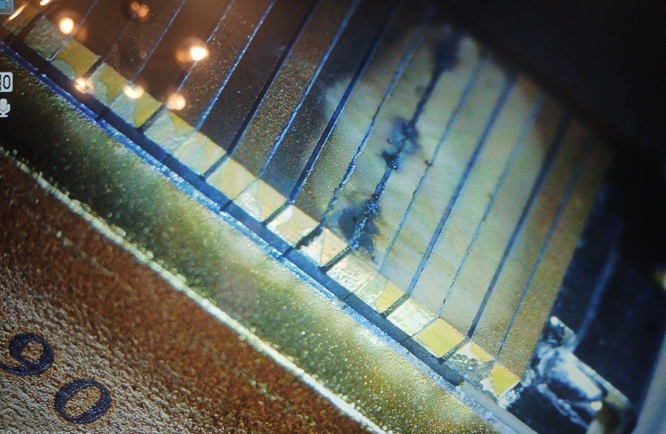

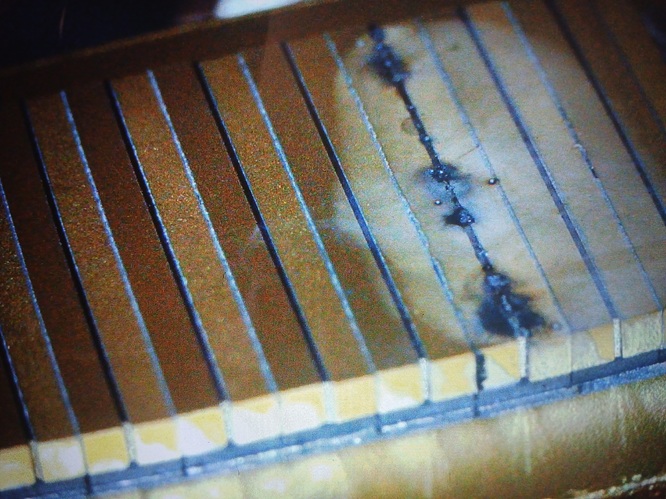

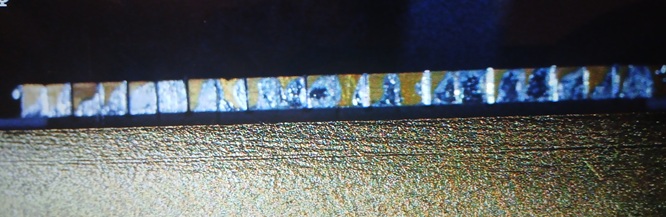

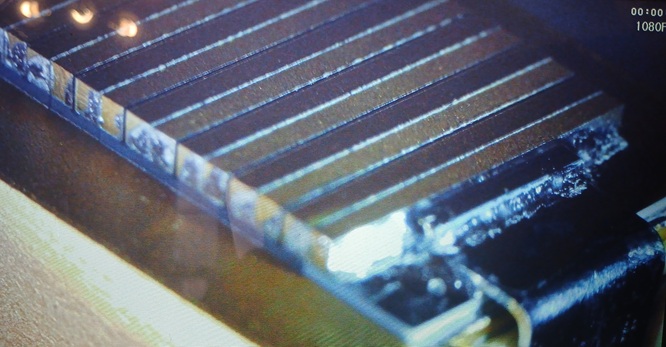

The photos below show a diode stack under a microscope. You can see that one strip (bar) looks different from the others. In this case, the black dots from overheating are really noticeable. This is the easiest way to tell that the diode stack is broken.

Is it possible to repair a laser manipulator diode stack yourself in your garage using a soldering iron without any experience? - THE DEFINITIVE ANSWER IS ‘NO’. All attempts to ‘revive’ an old stack will not produce the desired effect without special equipment. If you had a 10 bar diode stack, it operated at specific supply voltage parameters. You will not be able to operate normally with a 9 bar stack. (If a 500 watt 10 bar stack was installed in the handle, then a 500 watt 10 bar diode stack must be installed in the future).

Checking the diode stack with a laboratory power supply allows you to see the bars burning without using a cosmetic laser.

Experience in repairing hair removal lasers has shown that it is not always necessary to trust diode laser sellers, as some manufacturers exaggerate the parameters of their lasers for marketing purposes. If your diode stack has burned out, you need to disassemble the handle and look at the inscriptions on the stack. If you want to find out the power of your handle, please contact us.

I would like to remind you that the diode laser needs to be serviced and the water system needs to be cleaned, and the internal parts of your laser need to be blown out of dust. The water should be replaced once a month. Do not forget to change the water purification filters (unfortunately, cheap lasers do not have them).

CONDUCTING MAINTENANCE WILL INCREASE THE LIFE OF THE LASER.

Black stripes on the bars indicate that one of the bars has burned out. In this case, I will repeat, 10 bars. This diode stack is 37 mm high. The manufacturer installs 4 to 12 bars in it in standard cases. The bars have a power of 50 or 100 watts. The standard radiation wavelength is 808 nm, but there are diode stacks with 2 and 3 wavelengths simultaneously. In this diode stack from the manufacturer HPL, there were 10 bars of 808 nm, all with the same brightness.

In some versions of diode stacks, wavelengths of 755 nm and 1064 nm are used, and the most interesting thing is that 1064 nm is not visible to the human eye, but can be seen through mobile phone cameras.

Another photo of diode stack bars under magnification. In this case, a macro channel stack.

Photo under a microscope of laser bars soldered from the side. This is a macro channel diode matrix, and the bars are soldered in a row on a ‘substrate.’ Poor soldering will result in the failure of the diode stack. AN INTERESTING FACT IS THAT DIODE STACKS OFTEN STOP WORKING NOT BECAUSE OF BURNT BARS, BUT BECAUSE OF SOLDERING PROBLEMS. Due to poor soldering, the required current does not flow and the power sources go into protection mode.

This article was written by Romshi, an expert in cosmetic lasers. I have tried to include a sufficient number of photos of a non-functioning diode stack, including some taken with a microscope. If you are having problems with your diode laser, you can consult us about purchasing diode stacks. We also offer new diode lasers for hair removal at factory prices. These feature modern design, an Android system, worldwide delivery of cosmetic equipment, quality assurance, and international certifications. For consultations, please call +79180110234 (WhatsApp, Telegram).

Finding parts for repairing hair removal laser handpieces is important for novice technicians from different countries. One of my areas of expertise is repairing hair removal lasers, and I am a supplier of diode stacks of various power ratings and configurations. I work with repair technicians and retail customers from around the world. I am always ready to help people from other parts of the world. Write your question and I will try to help you. With respect to all, Romshi.

How to choose a diode laser for hair removal - choosing a hair removal laser.

What is an 808 nm diode stack, types, testing, and replacement - link about choosing diode stacks.

I also recommend reading the following articles on the ROMSHI.COM website.

We offer modern diode lasers for hair removal - link to diode lasers for hair removal

This was the column "Expert ROMSHI talks about lasers".