Laser diode stack 808nm: differences, how to check and change. Article from ROMSHI hair removal diode laser repair expert. What to do if the hair removal laser does not give the effect of hair removal!

How to understand whether the diode stack is working, how to change it in the laser handle, where to buy and nuances - you will learn this from the article by the expert on diode lasers ROMSHI.

The main reason for requests for repair of diode lasers from the practice of repair: when pressing the button of the manipulator stopped going flashes, there is no characteristic light from the window of the handle. A characteristic feature that on the screen works flash counter, but in reality flashes do not occur. This means that the button in the device is intact and the software works, but the diode stack power supply unit "goes with current protection". That is, the required current (for example, 40 amperes) simply can not pass through the diode stack and immediately triggers protection. Often the problems can be seen visually.

MAIN DIFFERENCES OF DIODE STACKS.

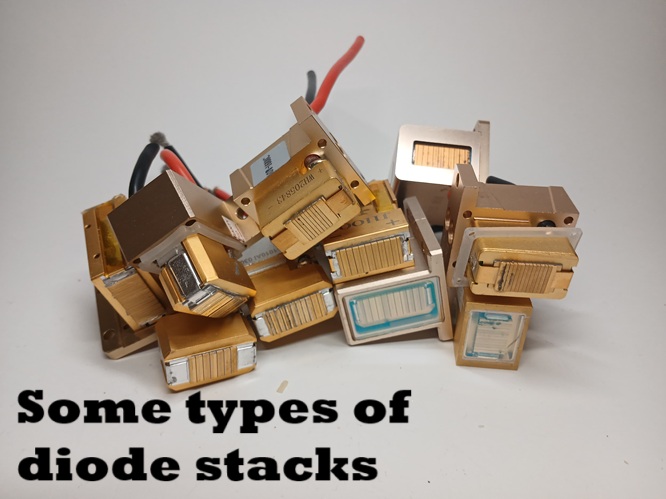

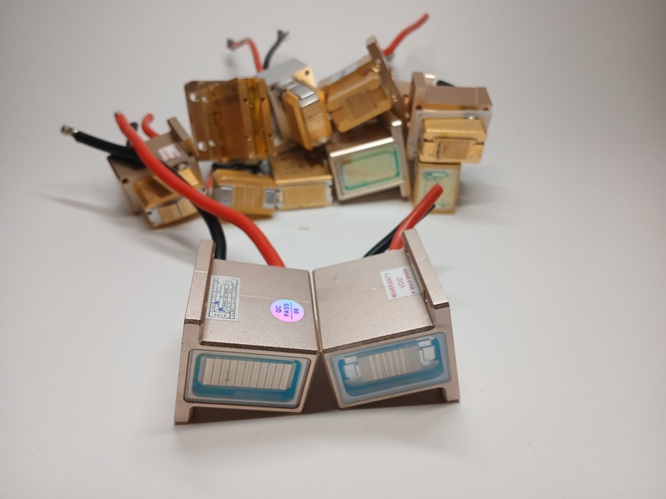

What is a diode stack in simple words: a part that is located in the handle of a diode cosmetic hair removal laser. Synonyms for diode stack: laser emitter, laser module, diode stack, laser bar, diode matrix, diode assembly to name a few. This part emits light with a wavelength of 808nm, which allows for so-called “laser hair removal” when interacting with human hair. These parts differ in the number of bars ("luminous bands" when the laser is working), the power of each bar ( usually 50 or 100 watts for 1 bar), the height of the part itself ( 37, 47, 49 , 52 mm and other variants), the length of radiation ( standard 808nm, but there are 1064, 755, 810 nm), the color of the diode stack body itself ( gold color, blue, red) and inscriptions ( for example lst-1010ai, dvs-1010ai, ht10500 denote diode stack 500 watt 10 bar 808nm and these are interchangeable analogues). Agree that it is easy for a beginner to get confused, and in case of emergency repair, you need to solve the problem quickly. This is the most expensive part of the cosmetic laser and it has problems mainly due to overheating, as the ideal temperature of water is 23 degrees Celsius (note briefly that when the diode laser is working, heat is generated and the diode stack must be cooled and distilled water is used to remove heat. Filters are used to purify the water and radiators, tec modules and in some units Freon compressors are used for cooling. This is very brief and more detailed in other articles on ROMSHI.COM). In this article Romshi expert tried to show various nuances about diode stacks.

INFLUENCE OF WINDOW SIZE ON DIODE LASER EFFICIENCY.

I would like to point out that for laser hair removal efficiency it is important to consider energy density, i.e. consider the area of the handle window and the power of the diode stack. Many laser manufacturers in China deceive their customers with stories about laser power. Below I will give several examples so that you can see the differences visually. Some conscientious manufacturers of cosmetology equipment produce 1 version of the laser, but with different sizes of the handle window. The larger the window, the more the manufacturer sets the power of the diode stack. Hence the conclusion - if the purchased laser is not very effective from the very beginning, then it is possible to replace the laser handle. Yes, it costs extra money, but you will get results.

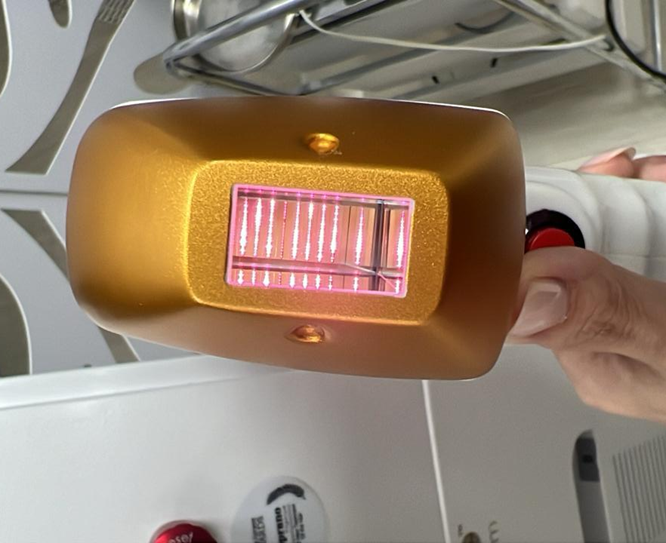

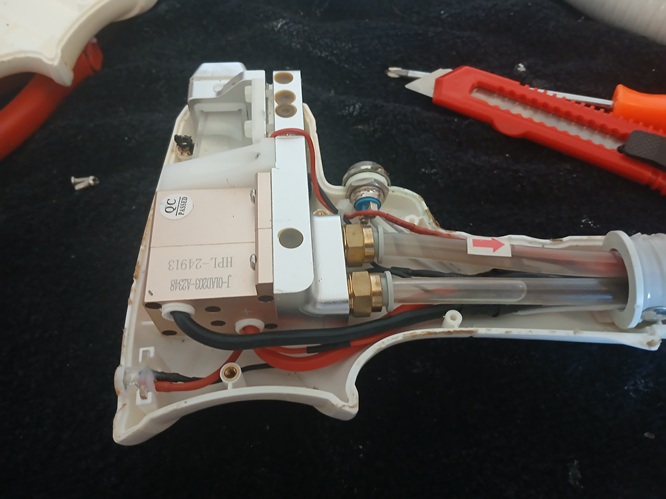

The photo below shows a large window when compared to a diode stack. Visually, the bars take up only part of the space. The handle has a 600 watt 12 bar diode stack, but this is a small power for the overall size of the handle window. Ideally, there should be a 1200-1600 watt stack there.

The photo below shows a stack with burning bars. In this case, it is more than 1000 watts, since the stack is micro channel. 1 plate produces up to 100 watts.

HOW TO CHECK A DIODE STACK USING A LABORATORY POWER SUPPLY UNIT.

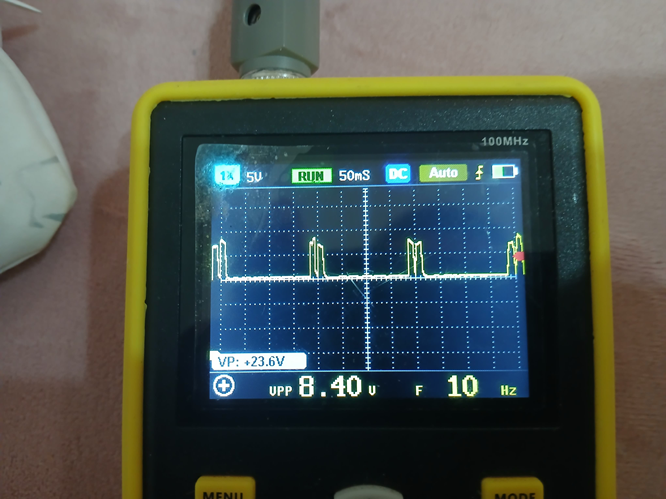

This photo shows an oscillograph when checking the operation of the diode laser hair removal handle. It is visible that there are surges and probably problems with the electronic part.

This photo shows a 808nm diode stack, where you can visually see that the brightness of its bars is different. In this case, the problems were caused by problems with the electronic part of the laser.

A diode stack operates when a voltage of no more than 1.8 volts is applied to 1 bar. The number of bars in diode stacks may vary. For example, diode lasers often have a 500 watt 10 bar diode stack. This means that 1.8*10= 18 volts of direct current of a certain shape will be applied to this part during operation. The part itself is designed for a current of 50 amperes. To test the diode stack I use 1.7 volts multiplied by the number of bars and a current of 1.3 amperes. This is enough for the bars to glow in a working diode stack. In a non-working diode stack there will be no radiation or not all bars will light. IMPORTANT NOTE: sometimes the diode stack glows evenly from the lab power supply, but when used in a laser there is no radiation. In this case, the current protection in the laser hair removal device will be triggered, since there is probably poor soldering inside the diode stack and the required current cannot pass in the required amount.

BRIEF INSTRUCTIONS FOR REPLACING THE DIODE STACK IN THE HANDLE OF A COSMETOLOGY LASER.

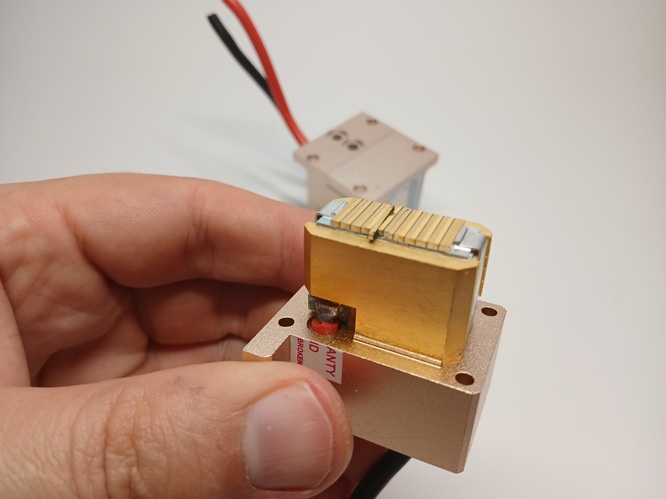

1. The problem was determined to be a degraded diode stack. It may be black dots on the bars, tin that has come out and shifted bars from their places (everything should be symmetrical, like on a new one), water drops inside the diode stack (it should not be and it indicates problems with sealing the laser module), broken glass on the side of the bars, the light from the brightness of the bars either stopped shining at all - or became uneven and other visual problems.

The photo shows problems with the prism and the protective glass of the diode stack. In this repair of the laser handle, it will be necessary to change the prism and the diode stack. In some cases, it is impossible to find a prism and we can offer completely different laser handles instead of the old one.

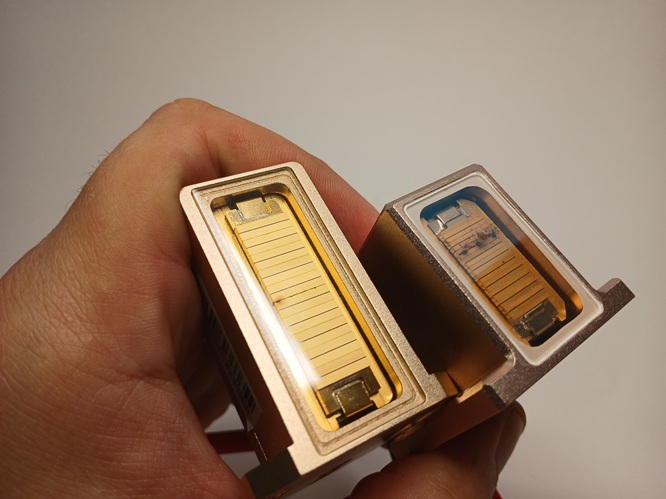

The photo shows problems with damaged burnt bars, as black stripes on the parts are visible. You can immediately see that the parts also differ in height. The number of bars in both cases is 10 pieces. But the left stack is 1000 watts, the right one is 500 watts.

In this photo you can see that 1 bar just "floated" on the molten tin. This is a sign of overheating. This is a common problem in diode stacks if the device does not provide high-quality water cooling. Buying the cheapest laser is not the best idea in my opinion. I offer my clients only high-quality equipment.

2. You need a replacement diode stack separately and I can offer these parts at factory price. Sending spare parts and shipping worldwide from China and Russia. Our advantages: quality, minimum price and online consultation on replacement. Quick consultation by phone +79180110234 in whats app, telergam ( ROMSHI laser repair expert ).

3. Disassemble the plastic body of the diode laser handle. Some handles have hidden bolts, so you need to do your work carefully. IT IS IMPORTANT TO TAKE PHOTOGRAPHS OF ALL STEPS SO AS NOT TO "GET CONFUSED WHEN ASSEMBLYING the handle back". I advise you not to rush, since some laser handles have an information screen and there are thin wires inside that can be torn off when disassembling the handle.

4. When you have opened the plastic case - you will have to replace the diode stack itself. Pay attention to how the wires are located, how the old diode stack is located. You will need to solder 2 wires of the new diode stack and solder them in the same way as the old ones were soldered. This is about 10 cm from the diode stack. The wires need to be soldered well with a soldering iron, and not just twisted without soldering with tin. In diode lasers, the current from 30 to 95 Amperes will flow through the wires and high-quality soldering is required. I REPEAT THAT I can provide free consultation). The manipulator also has a prism, which is located at a distance of 1 mm from the glass of the diode stack. The surfaces must be clean, and for cleaning I use wipes for optical surfaces. If there is dirt on the prism, the dirt can burn. After soldering the wires, you need to assemble the handle body and you can go around the perimeter with a small amount of silicone. This will prevent dirt from getting inside the handle in the future.

5. After replacing the diode stack, you need to check the voltage signal. The ideal test is with an oscilloscope to see the voltage waveform. The diode stack shines with a frequency of 1 to 10 Hz when the laser is operating. Usually the voltage signal is no more than 1.8 volts per 1 bar. I will give a few examples for a clear understanding. If you have large voltage surges, then there are probably problems with the power supply and this can quickly spoil the new diode stack. THIS IS AN IMPORTANT PART OF REPLACING THE DIODE STACK IN THE LASER EPILATION HANDLE. I want to warn you again so that problems do not arise. Do not miss the opportunity to write for advice.

6. After replacing the laser module and checking the electronic part, you need to clean the device from dust and clean the water system. To blow out dust, you can use a compressed air can. If there is a lot of dust on the radiators, then the water cooling is worse and slower and, therefore, the diode stack will last less. The higher the temperature of 23 degrees Celsius, the shorter the service life of the diode stack.

This photo shows a damaged laser handle prism. Even if your diode stack is intact, you MUST change the damaged prism. If you do not change the prism, the radiation from the stack will be reflected and it will overheat and damage itself. There should be no stains or dirt on the prisms in the path of the light beam.

This photo shows the problems of visually burnt diode stacks. Such stacks were replaced with new ones.

This photo shows an example of the internal structure of a macro channel diode stack. That is, there are bars on 1 plate. This is an article with examples of macro channel stacks.

This article was compiled for you by Romshi, an expert in diode laser repair for hair removal. The laser diode stack is the “heart” of a diode laser for hair removal and the most expensive element in a diode laser. The standard emission length is 808nm, which is effective in removing human body hair. If after laser hair removal procedures stopped “hair loss”, then the frequent problem is a burned diode stack.

In this article, I will show photos of diode stack problems that I came across in the process of repairing cosmetology equipment. I represent a factory that manufactures diode stacks and can offer quality replacement parts for diode laser repair.

Quick consultation by phone +79180110234 in whats app, telergam ( ROMSHI).

An article about the structure of diode lasers is available at the LINK.

I would also like to note that I can offer modern high-quality cosmetology equipment for a cosmetology office. Upon request, you will be able to see the prices.

In this article I tried to explain as clearly as possible what diode stacks to choose, how to check them and how to change them. Repair of diode lasers for hair removal requires specific experience, but online consultation will help you to repair your equipment easier. This is the first article in this section.

Quick consultation by phone +79180110234 in whats app, telergam ( ROMSHI).