Peltier elements in diode lasers. How the cooling system of the handle for comfortable hair removal works.

The Peltier element in the diode laser handle device is simply explained as follows: a special flat plate that becomes HOT on one side and COLD on the other when voltage is applied. Thanks to its operation, the tip of the diode laser remains cold. Read more below.

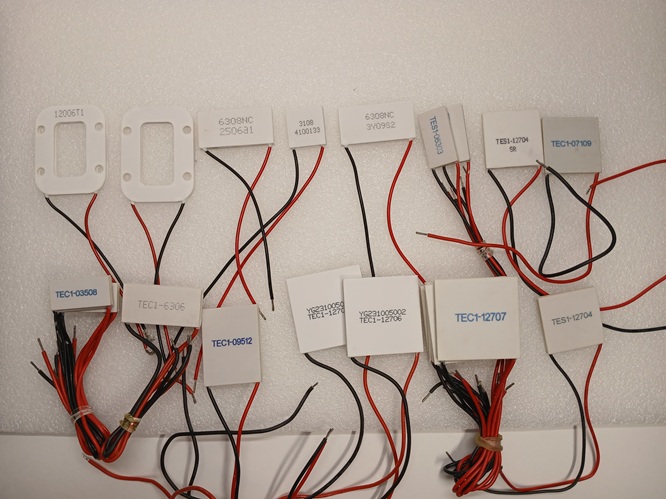

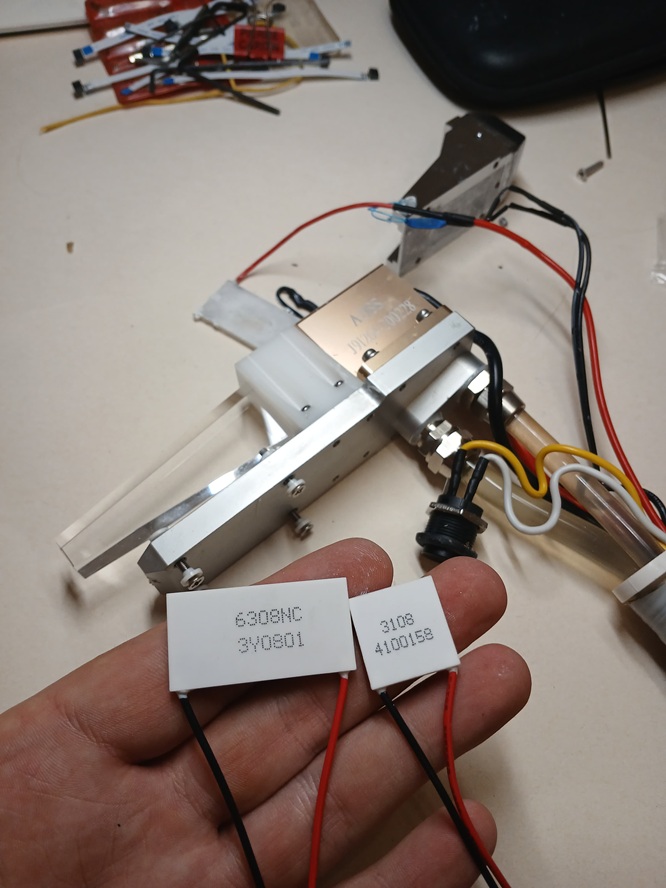

Peltier elements are an important part of the diode laser handpiece for comfortable hair removal procedures. In this article, ROMSHI experts will provide examples of photos of repairs and spare parts from hair removal laser repair projects. The photo below shows a small selection of Peltier elements for cosmetic lasers. Free consultation on problems with hair removal lasers by calling +79180110234 on WhatsApp or Telegram.

This article was written by Romshi, an expert on diode lasers for hair removal. If you use a laser in your work, you may have noticed that the laser tip becomes cold during operation. Peltier elements are responsible for cooling the tip. Their integrity affects stable cooling. The article includes photos of laser handles and Peltier elements, tips for checking them, and some nuances of repairing hair removal lasers.

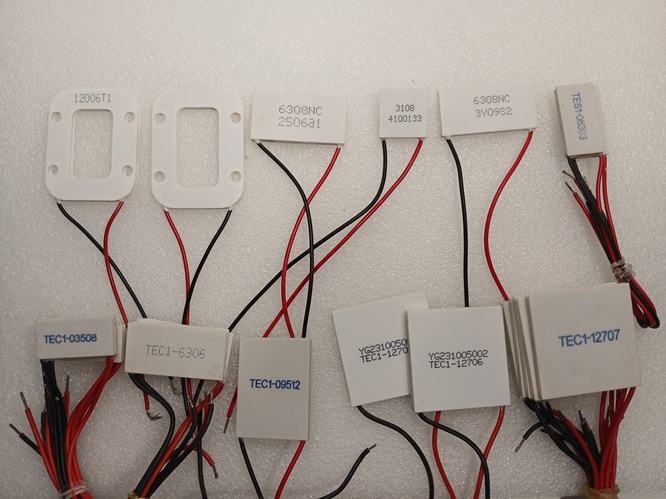

The photo shows square, rectangular, and oval Peltier elements. A Peltier element with one size, for example, 30*30*3 mm, can be designed for different currents. Tec-12704 and tec-12709 differ in their maximum permissible operating current. However, the opposite can also be true: the inscription on the Peltier element tec-12704 can be found on parts measuring 30 x 30 mm, as well as on parts measuring 40 x 40 mm. If you have determined that the Peltier element is faulty, it must be replaced with one that has the same geometric dimensions and is designed for at least the same current.

Peltier elements are plates with two sides. When a constant voltage is applied to the plate, one side becomes cold and the other side becomes hot. In diode laser handles, the cold side becomes cold, and the other side usually touches the aluminum interior of the handle, through which water circulates. The water dissipates heat and also passes through the diode stack, where it also dissipates heat. It is worth noting that the water system in a diode laser device plays an important role, but its design will be discussed in other articles in this section.

The photo below shows a disassembled adss fg2000b diode laser pen. This pen has two Peltier elements. Usually, if one element fails, the second element is still functional.

Peltier elements used in diode laser handles come in different shapes (square, rectangle, oval) depending on the manufacturer of the cosmetic laser and the design of the handle. The article provides photos of various options. IT IS IMPORTANT TO NOTE THAT PELTIER ELEMENTS ARE LUBRICATED WITH THERMAL PASTE FOR BETTER HEAT TRANSFER. Ideally, the thermal paste should be replaced every year to ensure that the diode laser handpiece cooling system works properly. This can be done yourself if you get advice and do everything carefully. By the way, FREE CONSULTATION is available by phone at +79180110234 on WhatsApp, Telegram (ROMSHI).

How to use thermal paste for applying to Peltier.

1. You need to remove the old thermal paste, for example, with wet wipes.

2. Before using a new Peltier element, I recommend testing it with a multimeter with a resistance of several ohms. Another method is to take a battery and attach it to the ends of the Peltier wires. This is a simple way to check in a fraction of a second whether the sides of the Peltier element are cooling and heating.

3. Apply a thin, even layer of thermal paste to the new Peltier element and carefully reassemble the pen. For repairs, I often used thermal paste to cool computer processors.

4. Once the pen is assembled, test it on a working laser device.

The photo shows an example of an oval Peltier element. Different laser manufacturers use different Peltier elements. It is important to consider the size of the old Peltier element in order to order the correct replacement part.

Let's consider an example related to the problem of cooling the handle of a cosmetic laser. The main repair request: the laser tip is no longer cold and quickly becomes hot. The following problems can be identified with poor handle cooling:

1. Faulty Peltier element.

2. A broken wire in the handpiece through which voltage is supplied to the Peltier element.

IMPORTANT NOTE: Some handpieces have several Peltier elements installed at once. I have seen 1-4 Peltier elements in a diode laser handpiece at the same time.

3. Problem with the power supply or sometimes with the connector on the circuit board. That is, a large current is supplied to the Peltier element and the connector burns out and no longer conducts electricity well.

4. The thermal paste has not been changed for a long time and has become too dry for normal heat transfer.

If you need advice on the repair and maintenance of cosmetic lasers, please feel free to contact me. Free online consultation by phone +79180110234 via WhatsApp or Telegram.

When repairing laser handpieces, visual inspection is often important. I recommend carefully disassembling the handle and checking the integrity of the wires. If you remove the handpiece connector from the device, you can check the resistance of the Peltier element using a multimeter. Many people have a multimeter in their household.

This material was compiled for you by Romshi, an expert in the repair of diode lasers for hair removal. Peltier elements are an important component of any diode laser handpiece in the field of cosmetology. There are a huge number of devices and a wide variety of Peltier elements on the cosmetology market. But if you have a cooling problem, the first thing to check is the Peltier elements.

Another important note about Peltier elements. In my experience repairing hair removal lasers, I have noticed that the laser handle can become cold, but when radiation is applied, the tip quickly heats up. In such situations, I recommend replacing the Peltier element with a new one. IMPORTANT: Peltier elements have a model designation on one side. When the voltage polarity is selected correctly, the side with the inscription becomes cold.

I also recommend reading the following articles on the ROMSHI.COM website.

How to choose a diode laser for hair removal - choosing a hair removal laser.

What is an 808 nm diode stack, types, testing, and replacement - link about choosing diode stacks.

We offer modern diode lasers for hair removal - link to diode lasers for hair removal

I would like to note that Peltier elements are also used in tec modules, which are used to cool water in, for example, adss, honkon, and mbt lasers. This is a topic for another article about the features of the water cooling system for diode lasers.