Diode lasers for hair removal (808 nm) are equipped with powerful cooling systems (water + air + semiconductors), so they are quite resistant to dust. But dust is one of the main enemies that cause overheating. It clogs ventilation grilles, filters, and radiators, blocking airflow and heat dissipation.When does overheating from dust begin?

Light dust (regular room with daily cleaning) — almost no problems. The laser works fine for months.

Medium dustiness (room without regular cleaning, construction nearby, or high client traffic) — after 1–3 months, the first signs may appear: the laser heats up faster, the fan gets louder, errors like "overheat" possible.

Heavy dust (room uncleaned for weeks, visible dust on surfaces, no filters or they are clogged) — overheating can start in just 2–4 weeks of intensive use. The device shuts down for protection, power drops, risk of damaging the stack or handpiece.

Real examples from practice and manufacturer recommendations:

If filters haven't been cleaned for 3–6 months — chronic overheating, stack resource drops by half.

In a dusty room (like "construction dust" or no air conditioning) — overheating is possible even with a clean device, because dust settles on optics and absorbs laser energy.

How to avoid it

Clean external grilles and filters weekly (vacuum + compressed air).

Full internal cleaning — every 1–3 months (or per manual).

The room must be clean: daily wet cleaning, air conditioner with filters, cover the device when not in use.

The room doesn't need to be "extremely dusty" — even moderate dust will kill the laser over time. Regular cleaning — and the device will last years without overheating.Yes, the effect of dust on heat dissipation in electronics (including laser equipment) is not just "clogs ventilation," but a whole set of interesting and sometimes unexpected effects. Here are some cool facts based on research and practice (including for cosmetology lasers):

Dust as a "thermal blanket": A layer of dust just 1–2 mm thick reduces heat dissipation by 20–40%. It acts as an insulator (dust thermal conductivity ~0.02–0.1 W/m·K, vs 200+ for copper in radiators). In lasers, this leads to diode stack overheating — temperature rises 10–20°C faster.

Temperature increase by 15–30°C: In computers and similar electronics, dust on radiators raises CPU/GPU temperature by 15–30°C. Same in diode lasers: stack overheating shortens flash resource 2–3 times (from 10–20 million to 3–5 million).

Dust + humidity = conductor: Dry dust is a dielectric, but with moisture (even 20–30% room humidity) it becomes a semiconductor. Can cause shorts or current leaks, especially in power supplies.

Reduced fan efficiency: Dust on blades increases motor load — fan louder but less effective (airflow drops 30–50%). Critical for handpiece cooling in lasers.

Thermal runaway: In extreme cases, dust causes "thermal runaway" — components heat up, dust heats more, conductivity rises — cycle to failure.

In industrial lasers: Dust on optics (lenses, mirrors) absorbs the beam — local heating to 100–200°C, cracks or coating damage.

0.5 mm dust layer = +10°C: Experiments show even a thin layer on heatsink raises temperature 5–15°C, thick — up to 50°C.

Dust accelerates corrosion: With moisture, causes contact oxidation, worsening heat transfer from chips.

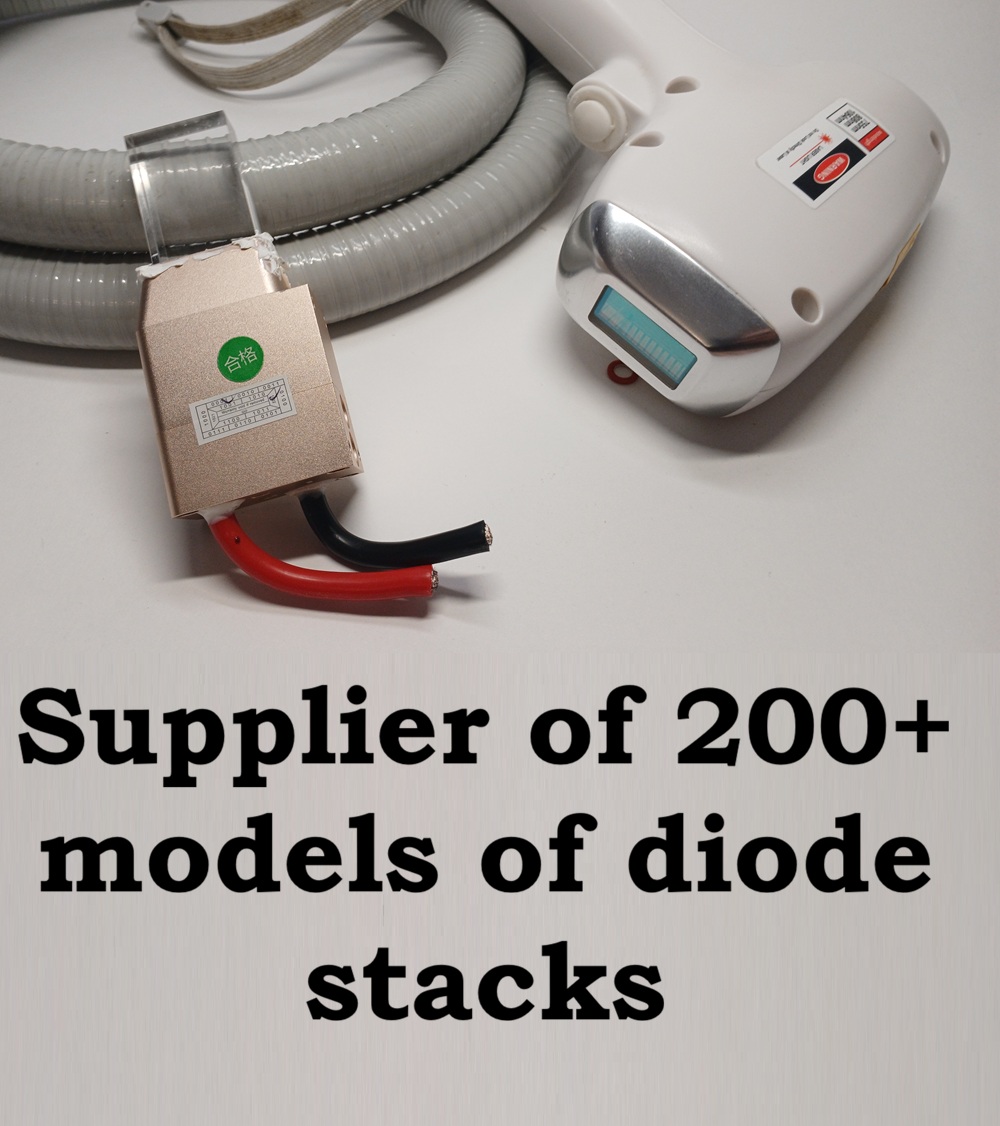

Romshi — Manufacturer of 808 nm Diode Stacks

Supplier of Laser Hair Removal Machines & Spare Parts www.romshi.com

+79180110234 Sale Laser Spare Parts. Shipping from China